Part 1: Warehousing, e-commerce, and capacity

As the COVID-19-related disruptions continue - and in some cases intensify - fulfillment operations has become one of the links in the supply chain most consumed by disruption. After a surge in demand during the pandemic, the need for e-commerce has continued to soar (Figure 1), and while inventories have finally caught up, the capacity for warehouses to deal with the continued elevated demand and corresponding rise in inventories has shrunk. In an effort to ensure staff safety and keep businesses operational, all too many warehouses have either paused or completely abandoned their improvement programs that would address these issues. However, now is the crucial time for warehouses to not only address these issues but to also anticipate future problems.

Figure 1: E-Commerce Sales Growth Q1 2019 – Q1 2021 (U.S. Department of Commerce)

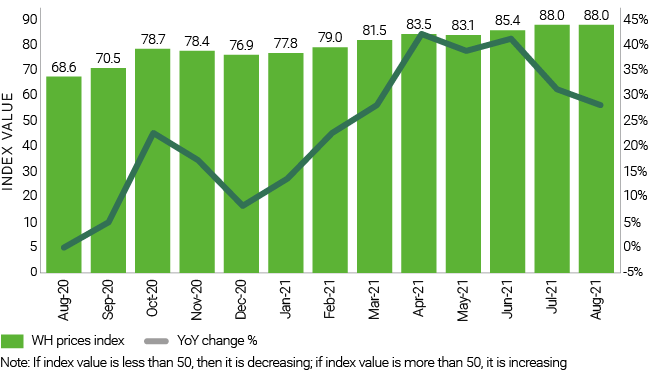

As operations pick back up from their peak pandemic slowdowns, warehouses will need to re-assess business as usual. They should be strategic and look to their improvement programs – or create them – to maximize productivity and utilize their warehouse capacity (Figure 2). With each ebb and flow of restrictions with emerging COVID-19 variants, operations leadership worldwide will be under increasingly intense pressure to resume and accelerate cost-reduction initiatives. Any relaxation of productivity metrics will need to be reversed to keep up.

Figure 2: Warehouse Pricing Index and Year Over Year (YoY) Change (www.the-lmi.com)

To add to the growing list of complications for warehouses, capacity is tighter than ever before, with over half of the space currently under construction already being rented out (Figure 3).

With the rising costs of construction materials and given that construction can take a year or more, we will likely see a supply/demand imbalance, especially pronounced in urban areas that have become critical components in e-commerce fulfillment.

Figure 3: Warehouse Capacity Index and Year Over Year (YoY) Change (www.the-lmi.com)

So what can be done?

To successfully emerge from the setbacks of the pandemic, there are key considerations and steps that warehouse fulfillment teams should take, including:

1. Re-start continuous improvement programs

- Now is the time for teams to take the opportunity to re-assess and take a clean sheet approach. It is important to evaluate what worked well - or didn’t - in the past.

2. Configure your warehouse for the ‘new-normal’

- A change in demand patterns has likely left the configuration of current warehouses outdated and inefficient, so it is crucial to re-configure warehouses to catch up with current and projected demand patterns, potentially requiring a complete re-design of fulfillment capabilities. This is especially important in industries with a renewed focus on e-commerce or those that focus on fulfilling smaller order quantities.

This is part of a series on warehouse optimization post-pandemic. Stay tuned for my thoughts on how labor shortages will affect warehouses, and how automation can be an asset to this link in the supply chain.

/Passle/5e1358328313d50770039d23/MediaLibrary/Images/6093fd71e5416b04ac4aebca/2024-01-09-14-29-41-938-659d5855146256acfd0a0c9b.jpg)

/Passle/5e1358328313d50770039d23/SearchServiceImages/2024-04-18-13-21-01-803-66211e3d7330266071d541da.jpg)

/Passle/5e1358328313d50770039d23/SearchServiceImages/2024-04-16-18-48-31-181-661ec7ff631126c32d270bbb.jpg)

/Passle/5e1358328313d50770039d23/SearchServiceImages/2024-04-16-07-49-16-790-661e2d7c4025ff662f6862d1.jpg)