With economic recovery in sight and increasing demand, commodity prices seem to be on an upward trend. While recovering industry, fiscal stimulus and investments in green infrastructure are driving stronger demand for metals in particular, the prices of agricultural products also appear to be volatile and increasing, presenting a call-to-action for food and other consumer goods producers.

Are higher commodity prices here to stay?

Early in 2020 we saw near-zero – momentarily even negative – crude oil prices. As it stands, oil prices have recovered back to pre-pandemic levels. Exceptionally high prices of oil-based commodities are therefore only partially based on the underlying oil price, while availability now is a more important price driver as producers struggle to ramp up their product capacity quickly enough to meet recovered demand.

Soybean price increases are partly driven by China, whose pork industry is recovering after African swine fewer disease. Increases in corn prices are also partly driven by Chinese demand. Other factors include lower production figures, Argentina suspending exports to secure domestic supplies and potentially recovering demand of industrial ethanol. Wheat prices are driven up by lowered production forecasts in addition to Russia introducing a duty on wheat exports earlier this year. An increased focus on sustainability also has impacted at least soy and palm oil prices.

Logistics are becoming more expensive as well. Corrugate prices are driven both by demand and supply. Demand has increased as shopping has moved from the high street to Amazon and other online retail activity, while on the supply side pulp and paper producers have spent recent years consolidating and cutting production capacity. Freight costs are heading to highs as well with increasing demand and fleet and labour shortages.

So, are these increasing commodity prices just a short-term uptick, or do they mark the beginning of a boom or even a year-long commodity supercycle? Many of the underlying drivers – production capacity, trade barriers, calls for greater sustainability and “new normal” consumer behaviours – are structural in nature. This means it is highly likely that commodity prices will remain elevated at least in the mid-term, potentially even longer.

The time to act is now.

Ensure the availability of critical raw materials

Elevated commodity prices are a signal of the current mismatch between demand and supply. Ensuring the availability of critical raw materials and safeguarding production should therefore be the first step any consumer products company should take under current market conditions.

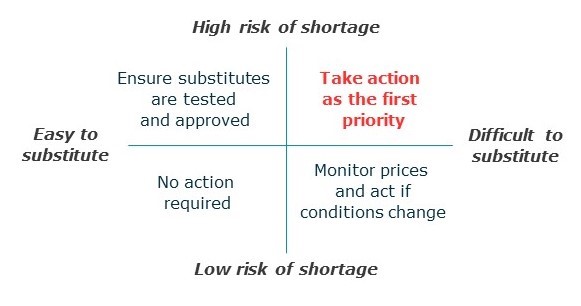

The practical steps to follow may be different depending on the type of raw material and process, but can be summarised as follows:

- The Sales and Operations Planning (S&OP) function must produce accurate forecasts for the demand of raw materials and, where there is uncertainty, provide a likely volume range so that the entire organisation has visibility on future requirements. Drive raw material requirements from the S&OP and communicate the forecast across the supply chain regularly.

- Put yourself “at the front of the queue” by issuing purchase orders or reservations far ahead, converting them to firm orders ahead of the jointly agreed “frozen period”.

- Strengthen relationships with suppliers to ensure that if they have to prioritise, they will choose you over another company. Regular communications are a simple but effective tool to do so and will pay off irrespective of the commodity cycle.

- Measure supplier lead times and on-time delivery performance as a key part of the supplier scorecard. Don’t wait for issues to escalate – address any deviations early and forcefully. Require suppliers to provide transparency on the situation and put in place action plans to resolve any issues.

- Build service level agreements and service debits & credits into supplier contracts

- Remember that securing ingredient availability doesn’t necessarily mean building up your own inventory levels – supplier commitments are as or even more important in building the “safety buffer”.

- In the longer term, work with the technical team to ensure that there are alternatives for critical raw materials, and that these are qualified for use.

Keeping up with commodities

While supply and demand issues were at play in commodities before the pandemic arrived, the COVID-19 shocks to the system in the past 16 months have only served to tip the balance. With a commodity boom highly likely to continue for at least the mid-term, securing the availability of critical raw materials is the first step. Beyond that, there are a number of actions for companies to take to ensure that any negative financial impact is minimised, and the organisation thrives. In future posts, we will explore these in more detail, including:

- Updates to commercial agreements

- Value engineering and new product development

- Production process performance

- Revenue management

/Passle/5e1358328313d50770039d23/MediaLibrary/Images/6093fd71e5416b04ac4aebca/2024-01-09-14-29-41-938-659d5855146256acfd0a0c9b.jpg)

/Passle/5e1358328313d50770039d23/SearchServiceImages/2024-04-16-18-48-31-181-661ec7ff631126c32d270bbb.jpg)

/Passle/5e1358328313d50770039d23/SearchServiceImages/2024-04-16-07-49-16-790-661e2d7c4025ff662f6862d1.jpg)

/Passle/5e1358328313d50770039d23/SearchServiceImages/2024-04-15-16-38-16-652-661d57f8de10b4f02f3aa40e.jpg)